Customized Straight Tuck End Boxes (STE Box)

Straight tuck end boxes are popular among various retail industries. These boxes come with a top and bottom flaps. The boxes fold from back to front or front to back and open to same sides. The locks in closing flaps help to keep inside contents secure. Thus, this type of packaging is highly spacious and offers enough room for customization. The versatility of these boxes makes them a perfect choice to pack various products. You can opt for these boxes either you have to pack cosmetics, food items, or pharmaceutical products.

Custom STE Boxes Tailored to Your Exact Size Requirements

The size of box is one of the most important parts of customization. We design STE boxes in whatever size you need. You can share exact product’s dimensions like its diameter, height and width. Our team will make sure to create a perfect size package in accordance to your specifications.

Sustainable Materials to Manufacture Durable Boxes

We offer various packaging materials. However, you can choose stocks according to your product’s needs. Here is the list of the most suitable materials to create custom tuck boxes.

Kraft paper is a preferred option because of its lightweight and biodegradable nature.

Unlike kraft, cardboard paper is coated. You can choose cardboard paper if you want to give packaging a glossy and shimmery look.

Corrugated packaging is ideal to keep products safe during shipping and shelf storage. Corrugated paper with thick flutes has strength to withstand handling pressures or traumas.

Add-Ons to Do Straight Tuck End Packaging

An exclusive design packaging looks appealing and has the power to withdraw the client’s attention. We add extra elements to give a special feel to packaging. Have a look at our available options:

Window in packaging is an excellent way to increase product’s visibility and exhibit your high-valued products before the audiences. Thick PVC sheet protects products against dust, dirt, germs and contaminants.

Inserts in boxes are added to enhance product shelf appeal and give clients a memorable unboxing experience.

Packaging with hang tab is ideal for display purpose. You can hang or swing products on front walls to grab consumer’s attention.

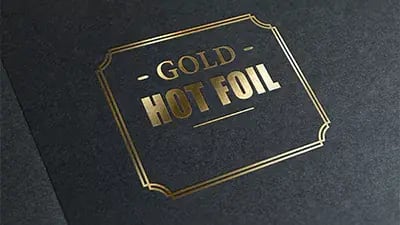

Premium Coatings & Finishes for Luxurious Boxes

We offer a wide collection of coatings and finishings to provide a delightful feel to the surface of RTE boxes. You can choose coatings like (gloss, matt, spot UV) to add an extra layer of protection and elevate visual appeal of packaging. Besides that, we use embossing; debossing and foil stamping to give luxury touch to box’s surface. You can choose any of these options to give a high-end look to boxes.

What are the Benefits of Using Custom Straight Tuck End Boxes?

Custom straight tuck end boxes are one of the most popular packaging solutions among different industries. There are plethoras of advantages of using these boxes. We have listed a few here:

- These boxes made with quality materials are highly durable.

- STE boxes have unique and stylish designs.

- They have easy assemble and shipped flat.

- They are fully customizable. You can get them printed with any design, graphics or texts.

- These boxes are highly affordable. Brands can choose these boxes without breaking their banks.

- Tuck end boxes made with recycled materials are 100% eco-friendly.

- They are a helpful tool for brand’s marketing and leave a good impression on the buyers.

Why Choose us?

Do you need first-quality custom straight tuck end boxes and are looking for an experienced packaging supplier online? Don’t look elsewhere. You have landed in the right place. Our company is a reliable and renowned packaging manufacturer in the USA. We offer remarkable products at affordable prices. The best thing is that our services are client’s centric and make certain to help client’s at all possible costs. You can connect with us to experience our phenomenal services. We offer:

- Free and fast shipping

- Quickest turnaround

- Zero charges for die-cuts and plates

- Free of cost digital 2d and 3D mock-ups

- Live chat support 24 hours

- Free and instant quote

- After sales customer support

Frequently Asked Questions

Q: How do straight tuck end boxes differ from reverse tuck end boxes?

Straight tuck end boxes are very like reverse tuck end boxes except for closing panels. STE boxes open in same directions, while RTE boxes open in opposite directions. For more detail cleck here

Q: What are straight tuck end boxes?

STE boxes are designed with a front and a back comprised of 2 sides and 2 openings. Both openings come with 2 flaps that are attached to the sides of box. They fold inward and larger flap fastened to the front of the box that folds over the side flaps and tucks into the side of the box.

Q: How are straight tuck end boxes assembled?

Straight tuck end boxes have both top and bottom flaps that tuck on the back side of the box. They are convenient to assemble as they contain closing flaps at both ends.

Q: Can straight tuck end boxes be used for shipping products?

Yes, they can be. With their flat bottom, these boxes are ideal to ship light-weight and luxurious products. However, STE boxes act perfectly as retail boxes.

Q: How durable are straight tuck end boxes?

Straight tuck end boxes are highly durable. These boxes are manufactured with sturdiest materials cardboard and corrugated papers. Thus, they last for longer and can withstand tears, sun light, moisturization and heat.

Q: What closure options are available for straight tuck end boxes?

Straight tuck end boxes with two sides of tucked flaps make them convenient to fold. The closure flaps are located on the bottom and the same direction with base folding in front and the top panel folding in the rear.

Q: What industries commonly use straight tuck end boxes?

Straight tuck end boxes are a preferred choice for retailers. They are used to pack a huge variety of products in retail industry. These include: cosmetics, food, bakery, small electronics, CBD oils and skin care products.

Q: What sizes are available for straight tuck end boxes?

We design custom straight tuck end boxes in all sizes. First of all, you have to share accurate product’s dimensions to get a right size package.

-Box-thumb-md.jpg)

-Box-thumb-sm.jpg)