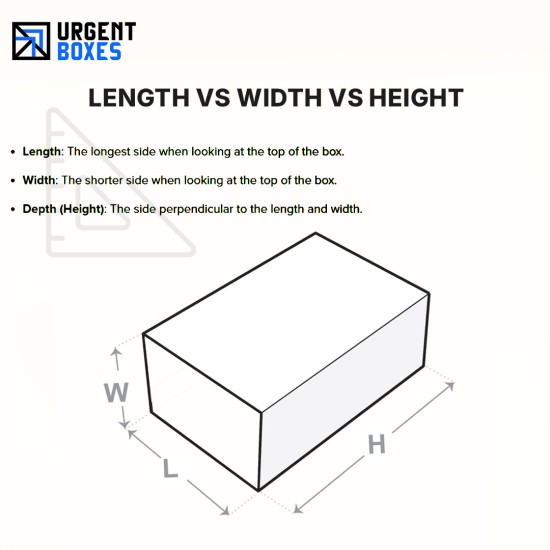

What Do Length, Width, and Height Mean?

The first thing that you should know is knowledge of all sides. You must know that which side represents what. You can understand this with simple example. The length, width and height are three friends that always remain together. However, each terminology has a different personality.

Length – Longest Side

The length is always the longest side of the box.

Simple example?

See your phone. The longest side is the length from top to bottom.

Width - Front of Length

Width is the shorter side that sits next to the length.

Imagine a book. The shorter side that goes across is the width.

Height – The Side that Goes Up and Down

Height tells you how high something is.

Think about a glass. The distance from the bottom to the top edge is the height.

Now apply this to a box:

- Length is the longest open side

- width is the shorter opening side

- Height is how high the box stands when held upright

This simple methodology helps you easily measure box dimensions. Everything becomes clear, and you can choose the correct packaging dimensions for your products.

How to Measure a Box Step-by-Step

Most packaging experts use the standard length × width × height format. This order is very important to measure the box in right way. If you are still confusing why this order is necessary to follow. Read this piece of writing to clarify the answer. This has very simple logic behind this. Let's make it a clear step-by-step guide.

To measure the box, you first understand the basic flow. The tool that you require for packaging measurement is tape. The following method gives you an idea how to measure dimensions of the cereal box every time.

Step 1 – Keep the Box on Flat Surface

Hold the box upright and open it in front of you.

It is important to keep the flaps open and out of the way.

With this method you will get correct overview.

Step 2 – Identify the Length

To check the length first find the box opening side.

The longest side is the length.

You can measure it from one corner to another.

Keep notes of it.

Step 3 – Identify the Width

Now measure the short side next to the length.

This is the width.

Hold the tape measure straight for accurate readings.

Step 4 – Measure the Height

Then measure from the bottom to the top edge of the box.

This is your height.

This shows how high the box will stand when held upright.

Step 5 – Write the Dimensions in the Correct Order

Always record your results as follows:

length × width × height

This format is the universal standard in packaging.

Step 6 – Double Check Your Goals

A quick recheck helps to avoid size errors.

The minor mistakes in packaging dimensions will change the entire packaging. It will affect product storage and shipping cost. So, check all things properly to avoid mistakes.

Inside vs. Outside Dimensions 1

When it comes to box measurements, this is the point where most people get confused. Internal and external dimensions may look the same, but they serve entirely different purposes. Knowing what you need can save you assembly problems, damaged products, and unexpected shipping costs.

Internal Dimensions

Internal measurements show the actual usable space inside the box.

These measurements tell you how much space your product needs to fit comfortably without squeezing. They are the most important measurements when designing packaging. It also helps check the fit of a product and plan inserts and partitions. If the inner shape is even slightly off, the product may not fit properly.

External Dimensions

Outer dimensions include the box's full size and the thickness of the additional material.

They matter when you stack boxes, place them on shelves, or prepare to ship them. Carriers use external numbers to determine how much space your package takes up. It can also affect shipping rates.

Why is the Difference Important?

Using the wrong measurement type can cause significant problems.

The internal dimensions ensure your product fits precisely inside the box. If you depend on the external dimension, it will lead to problems with the exact fit of products. Meanwhile, only the internal side measurement is not enough. For shipping calculations, both dimensions are essential. And if you do not follow this, you may end up with higher postage costs than expected. Understanding when to use each one helps you design better packaging. It also avoids returns and saves on shipping costs.

Common Measuring Mistakes to Avoid

It is not difficult to measure a box but it requires great care. The small errors can cause various problems for product packaging. It will give you poor product fit that can damage product. The other setback that you will get with wrong measurement is higher shipping cost. So, avoid the following mistakes and make great packaging.

1. Measure the Wrong Side First

Many people confuse length and width.

Always start by opening the box and identifying the longest side first.

2. Use Outside Measurements When you need Inside Measurements

The product's fit depends on the interior space.

If you measure the outer edges, the product may be too tight.

3. Measurement While Folding the Box

A bent box can distort the measurements.

Always open the flap and stand the box upright before measuring.

4. To Guess or Estimate

Ignoring it leads to costly mistakes.

Use a measuring tape every time – even for "light" sizes.

5. Forgetting the Thickness of the Material

Corrugated boxes can add noticeable thickness.

This affects external dimensions and shipping calculations.

Avoid these missteps and your measurements will be accurate, clean, and reliable every time.

Easy Real-World Examples

Sometimes, real objects explain things better than definitions. Here are some day-to-day comparisons that make the box dimensions easier to understand:

A book

- Think of a hardcover book.

- The longest side is its length.

- The shorter horizontal side is its width.

- The thickness is the height.

- It's the same way you measure a box.

A shipping package

- Imagine receiving a package on your doorstep.

- When you open the top flap:

- Is the length of the long opening side.

- The smaller opening side is the width.

- This is the height from the floor to the top.

- A Tissue Box

A Rectangular Tissue Box also helps:

- front = length

- side panel = width

- perpendicular size = height

For example, when measuring a tissue box, it’s important to know how to measure its length, width, and height correctly. Learn the complete tissue box dimensions guide here. Using everyday objects makes it easy and intuitive to understand the box's dimensions. If you can measure these, you can measure any packaging box with confidence.

Conclusion

The box measurement should be easy for customers. Knowledge of length, width, or height makes this process easier. You will get the correct box dimensions and a memorable client experience. The above guide is for your deep understanding. You can read this to avoid the errors and complaints. As the wrong dimensions will affect your brand reputation and customer loyalty. So, know this difference clearly and make the right decision. The right approach will make your journey easier and user friendly.

FAQs:

1. What is the correct order of box measurements?

The universal rule of packaging box measurement is length x width x height. This will give you the right answer.

2. How to get the correct length of the box?

It is a known fact that the longest side of a box is called the length. Look at the box's opening.

3. Is it essential to measure inside or outside dimensions?

Yes, both dimensions serve different purposes. The inside dimension will give you exact product fit, and the outside dimension will provide the correct storage and shipping dimensions.

4. What can change the shipping cost while the product is lightweight?

The wrong size or dimensions of a box can affect the shipping cost. Carriers use DIM weight. So, it means the box size affects the price, not the product's inside weight.

5. What tool is best to measure a box?

The popular tool for measuring a box is a tape measure. But you can use a ruler for smaller containers.

6. What if the size of any box is unusual?

Measure the maximum length, width, and height that completely cover the shape. Carriers measure the widest points.

7. Can incorrect measurement affect my packaging order?

Yes. The minor mistakes can cause various problems. It makes the box assembly more difficult or increases shipping costs. It also delays box production.

8. How to measure the box for inserts or partitions?

First, measure your product. Then design the box and insert around the exact size of the product.

![How to Measure Shoe Box Dimensions [Complete Guide]](https://assets.urgentboxes.com/storage/2409/conversions/STANDA~1-thumb-sm.JPG)