Often known as blister packs, these boxes are designed to offer a clear view of the product packed inside. Many times, when products are packed in layered packaging, they lose their purpose. Blister packaging allows your customers to make a quick purchasing decision based on the products. These boxes do have a transparent display. But they are also highly protective and portable. They securely hold your products inside the packaging. Moreover, their design is extremely convenient. You can carry these boxes with you everywhere.

If you are interested in learning every explicit detail about blister packaging, including its use, types, benefits, and application processing, then this article is all that you need.

What is Blister Packaging?

Any plastic packaging with a pre-formed cavity designed to hold a specific product inside is called blister packaging. This packaging comes with a sealed closure. This seal is mostly made up of plastic and is transparent. The plastic — PET and PVC seal cover makes sure that your products remain intact. These custom boxes offer an extended shelf life to your products. Blister packaging can help you increase the visual appeal and noticeability of your products.

Common Industries that Use Blister Packaging!

There are hundreds of daily-use products packed in these boxes. These boxes are used because of the appeal that they offer to the products. Their design makes it easy for customers to buy them. Because every customer is curious about what’s inside the box. And sometimes, it gets hard to buy a product without looking at it! Every such problem gets solved with blister packaging.

Let’s take a look at some common industries that use blister packaging:

Pharmaceutical Products: Products like tablets, capsules, bandages, and various small medical-related items are stored in these boxes. These boxes are also child-resistant, and they ensure complete product security.

Food and Bakery Items: Chocolates, mints, chips, cookies, bubble gum packaging, and various types of snacks are packed in these boxes. They are even used for subs and salads.

Electronic Appliances: Mobile chargers, earphones, memory cards, and USBs are among the few products that can be stored in these packaging boxes.

Stationery & Office Supplies: Markets, pencils, pens, erasers, and sharpeners are some common products that can be packed in these boxes.

From pharmaceuticals to skincare, these boxes are designed to hold versatile product types.

Functioning Process of Blister Packaging!

Let’s take a look at some common steps that are being followed through the making of blister packaging:

Analyse the Product Design and Prepare!

The first step is all about understanding the product type. After that, the dimensions of every side are noted down. Then it’s time to analyse the type of protection the product requires from blister packs. Then the designers create a design with the cavity measurements and material type. The design, color, and brand information everything is prepared in this step.

Choose Your Packaging Material!

There are two types of materials required to create this packaging. The first one is the material for the cavity, while the other is the backing material. Polypropylene, polyvinyl chloride, and cyclic olefin copolymer are some common material options for the cavity. On the other hand, for the backing material, aluminum foil, cardboard and paperboard, and lidding films can be used.

Create the Blister Cavity!

It’s time to create the blister cavity. First of all, a custom will be created. This mold will align with your product’s specifications. Next, it’s about time for the thermoforming process. This process ensures that the plastic gets heated up and transformed into the right shape.

Placement of Product into Cavity!

Now, you can place your products into the packaging. You can either place it by hand or with the help of a machine. If you have a short-run order, then manual placement is your ideal option. But for large-volume orders, automatic placement is a good option. Automated systems save you from placement errors, as they are highly accurate.

Seal the Packaging!

There are different types of sealing methods. Heat sealing, ultrasonic sealing, and cold sealing are the top three sealing techniques. Heating sealing is the most common among them all. But if the product being packed is heat-sensitive, then ultrasonic sealing is the best option.

Cutting the Packaging for the Final Design!

Once you are done with the sealing process, it's time to move on to cutting and separating the packaging. Die-cutting and laser cutting are two common techniques used for cutting purposes. In case of complex packaging designs, laser cutting will be the right approach. But if the packaging style is simple, then die-cutting will prove just fine for you. Once the edges are smoothed, the packaging is good to go.

Benefits of Blister Packaging for Your Products!

There are endless benefits of blister box packaging. Let’s explore a few together:

Guaranteed Security and Protection!

These packaging offers excellent protection for your products. The seal covering ensures your product’s freshness. Moreover, the seal ends do not allow any damage to the shape of your products. By incorporating child resistant packaging features, these boxes can also be made child-safe.

Highly Convenient and Portable!

This packaging style offers great convenience to the buyers and sellers. The one-compartment design allows customers to buy a smaller quantity of the product. Moreover, the highly portable design makes it easy for the customer to carry them around wherever they want.

Cost-Effective and Eco-friendly

These boxes reduce your product’s carbon footprint. Because this method doesn’t require large material quantities. On the other hand, blister packaging is also highly cost-effective.

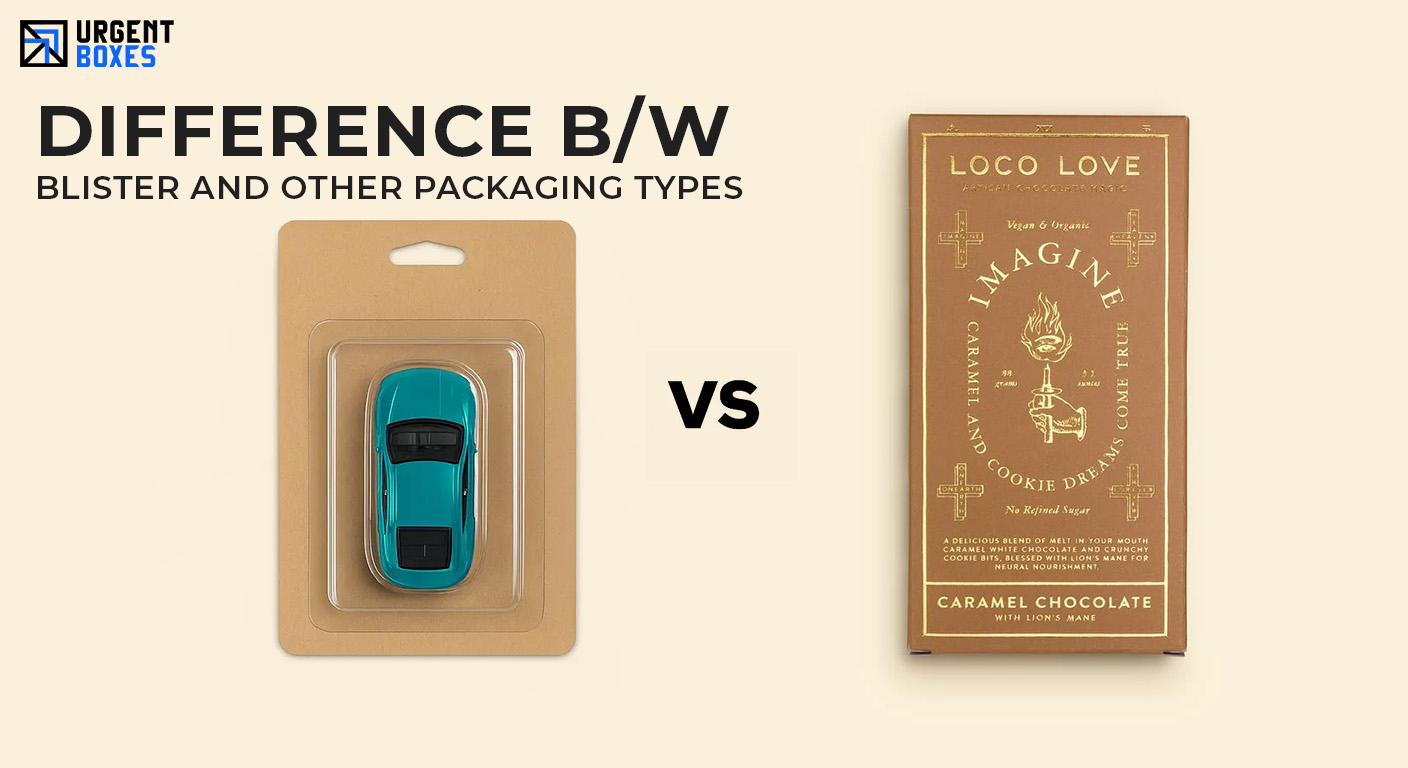

Difference Between Blister and Other Packaging Types!

Blister packaging is affordable, secure, and convenient. Whereas, if you consider sachet packaging, then it’s not that secure. Once you open the sachet, and you have used half of it, you can’t securely close the packaging again. This will increase the risk of spillage and waste. The same goes for the bottles. Once they are opened, the product integrity will start dropping.

Moreover, if talking about strip packs, then the common difference between them is their material. Plastic is commonly used in blister packaging. Whereas, for strip packs, aluminium is the preferred material.

Why Is Blister Packaging an Incredible Choice for Your Products?

Blister packaging is a smart and modern packaging solution. It is offering convenience, sustainability, and efficiency to many businesses. In the future, blister packaging is only going to get improved. There will be better tools and machinery to create these boxes. This method has promoted recyclability and reduced the use of plastic.

Wrapping It Up!

If you are looking for a reliable packaging supplier to create blister packaging for your product, Urgent Boxes is here to help you out!

![How to Seal Mylar Bag A Complete Guide [Updated] 2024](https://assets.urgentboxes.com/storage/1736/conversions/Step-By-Step-Guide-to--Seal-Mylar-Bags-Blog-thumb-sm.jpg)