The die cutting procedure stems from the letterpress printing. This technique is being used in the printing and manufacturing industry. This process allows beautiful cut-outs of a box into different shapes. It is used to create designs and cut out simple and intricate patterns. Businesses are using this technique to turn their ordinary packaging into beautiful custom boxes. This method is not only simple, but it is highly effective in enhancing the customer’s experience.

If you are looking for a cost-effective custom packaging solution, the die-cutting procedure will prove to be an excellent solution for you.

Dive into this article to learn about die cutting from scratch. We will understand the specifics of die cutting, its procedure, methods, types, benefits, and common mistakes that you should avoid while getting die-cutting.

What is a Die, Die-line, and Its Role in Die-cutting Technique!

Most people confuse die cut with die lines. Both of these terms are different from one another.

A die is a cutting tool. This tool is used to create unique shapes in any size and pattern. It is most commonly made of metal and can be used for a wide range of packaging materials. On the other hand, a die line is the mold or the layout that is used to make the cutout. It is used to create crease, cut, and perforation marks. A die line is highly important to achieve design accuracy. Learn more about dielines and their role in packaging and printing in our detailed guide What is Dieline Mean in Packaging and Printing?

Application Process: How Does Die-cutting Work?

With the help of the latest machines and technologies, the die cutting technique has been developed. It has become way more precise and efficient.

● The die-cutter is pressed on the packaging surface, creating the desired shape or pattern. The layout of the design is created by CAD. CAD stands for Computer-Aided Design.

● This design is then transferred through digital drawing of your dieline to the board. This board, also known as the dieboard, is mostly made up of wood. It is used to decrease all types of movements during the die cutting process.

● The next step is performed with the help of laser cutters. This laser-cutting technique is used to get accurate and more precise results. Before the final step, you need to make sure that you carefully create a layout for the bleed lines and cut lines.

Functions of Die Cutting!

Here are three of the most common functions that die cutting offers:

Scoring

It is used to cut through a specific part of the design. It improves the structural strength of the packaging. Moreover, it also offers a clean and pristine look to your packaging.

Creasing

To create a perfect fold, an indented line is created. This line then forms the crease. Crease offers functionality to your boxes. It saves your packaging from any destruction and deformity.

Perforation

Many boxes have a perforation-style cut. This design is created to make sure that even after removing a specific part of the box, the Packaging remains intact. It is perfect to offer an elegant look to your packaging.

Common Types of Die-Cutting

Different types of die-cutting techniques are used to obtain different results. Here are two of the most common die-cutting types:

1. Laser Die Cutting

This method is mostly used for cutting through plastics like PET, foam, silicone, PET, polyethylene, and polypropylene. Laser die cutting can be used to create minor design details. It can easily cut through materials with a higher density. This method offers simple and easy customization. Moreover, it also takes a shorter production time. The biggest cons of laser-cutting are high costs and the consumption of high-energy.

2. Rotatory Die Cutting

Tapes, magnets, film, paper, and foam are just a few of the materials that are used in the rotatory die cut method. This technique is suitable for various material types because of its flexibility. Moreover, you can use it to create complicated designs. This method is speed-efficient and is reliable if you want multiple cuts on different layers. The biggest disadvantage of this method is that you need a new die for every design.

Common Methods Used in Die-cutting for Your Packaging!

There are different types of methods used in the die-cutting process of your boxes. These methods are used for various types of custom boxes, including display boxes and window boxes.

Let’s take a look at some common methods:

Blanking

This process is used to create designs on a flat material. The flat surface is accurately positioned and sliced into the desired pattern. This method can also be performed on a giant packaging surface. Blanking is performed by two main components, known as a punch and a die. This technique is highly cost-effective. Moreover, it is highly suitable to obtain accurate results. In this method, there’s low material usage, which also leads to less material wastage.

Drawing

This method is more commonly used for rough and solid materials like glass and metal. If you want to create a multi-dimensional die-cut shape, then drawing will prove to be the perfect die-cutting method for you. This method is used to create lengthy shapes. Even tubes and strips can be created using this method. The drawing method is highly durable. On the other hand, it is also speed-efficient and offers great consistency in the results.

Broaching

This method is specifically designed to achieve perfection while cutting through hard material. It is perfect for wood and even metal. This method is quite famous because of its adaptability. Broaching makes sure that the die is cut to the right size and style. It elevates the overall performance of the die.

Advantages of Die-Cutting For Your Packaging!

Now, after learning about all aspects of die cutting. It’s about time you learn about some of the biggest advantages that this method offers:

Affordable and Cost-effective!

This method is highly cost-effective. The techniques used in this method require low costs. This method can be used for bulk orders and low minimums. It will remain cost-effective for both types of orders. This material can help you spend less money because of its maximum material usage.

Accurate and Consistent Results!

Die cutting tools are highly effective. They are perfect to get clean and consistent results. Moreover, the die cutting process creates accurate results for bulk orders. This method is also speed-efficient, and it is perfect for getting durable results.

Offers Great Versatility!

The die-cutting method is highly versatile. It can be used for all types of retail boxes. It is perfect for creating unique designs and creative shapes. This method is also great for attracting customers. It will also allow you to build a unique brand identity. Therefore, getting die-cut boxes will prove to be an excellent marketing strategy for you.

What Types of Mistakes Do You Need to Avoid in Die-cutting?

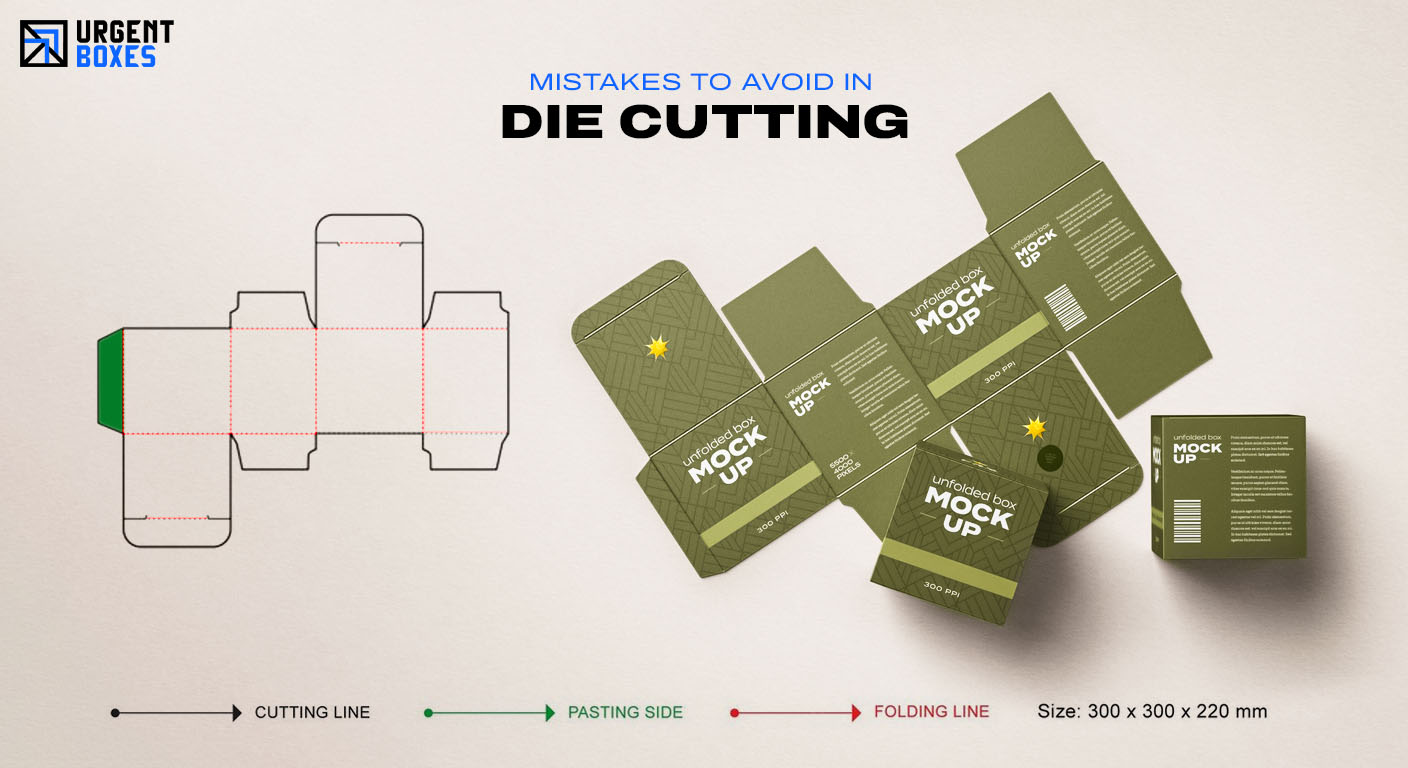

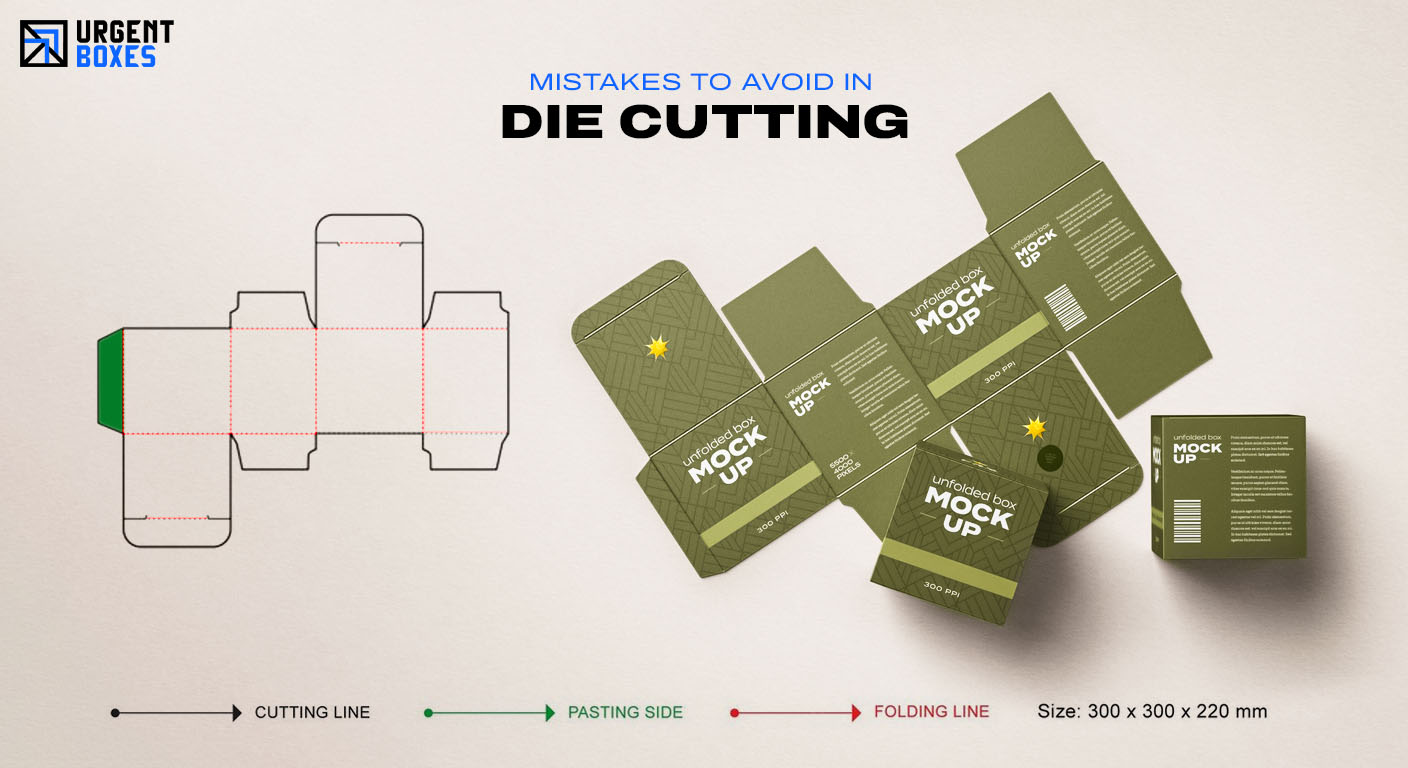

Rough Edges & Uneven Cutting

An incorrect pressure system, along with a dull blade quality, is going to create rough and uneven edges. This makes your packaging look bad and will also impact your reputation. This issue can be resolved by using the right material, sharp tools, and regular maintenance of the machines.

Excessive Creasing

When you crease and fold the design in an excessive manner, you will damage the structure of the packaging. Your bleed and fold lines will not be clear. This will damage the structural integrity of your packaging. The biggest cause behind this mistake is poor adjustment of the space between the rule and the counter plate.

Alignment Issues!

Sometimes, there’s noticeable misalignment in your design after the die cutting procedure has been performed. This not only affects the overall packaging appeal. But it also creates an unprofessional packaging box. Moreover, the main reason behind this is any type of specific mechanical wear or machine calibration. To avoid any such issue, you should regularly maintain your system. You also need to create a standardised calibration. This will also help in maintaining the alignment.

Conclusion!

Die-cutting techniques make customization easy for you. It offers a creative look to your packaging at reasonable rates. Urgent Boxes creates the perfect die cut designs for you. If you want to create a solid brand identity, place your order for die cut packaging now.